|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

Registered: Apr 2002 Dear

all, dear Vincent, Registered: Mar 2002 Vincent,

my first reaction to your post was to think that you may

really be on to something, but then I began to question

the premise. First of all, there isn't a reliable way to

determine whether a particular rug was woven on a vertical

or a horizontal loom. Secondly, haven't vertical looms

with rollers been around long enough that they could predate

even the oldest example yastik shown in this thread? Registered: Jan 2002 Dear

Micheal, Registered: Apr 2002 Hallo

everybody, dear Vincent, Registered: Jan 2002 Dear

Michael, Registered: Jan 2002 Maybe

it's a bit strange, but here's what my elongated dream

brought me: Registered: Apr 2002 Here

are a few thoughts, Vincent, on your “elongated dream.”

Registered: Jan 2002 Dear

Marla, Last edited by Vincent Keers on 10-31-2002 at

12:56 AM Registered: Apr 2002 Dear

Vincent, Registered: Not Yet Dear

Vincent, Registered: Jan 2002 Dear

folks - Registered: Dec 2001 Hi

Folks, Registered: Apr 2002 We could

diagram between 15 and 20 different ways that rug looms

have been set up by Middle Eastern and Central Asian weavers,

with a wide range of devices and methods for controlling

warp tension. It’s a problem that every weaver deals with,

and the solutions range from very simple and primitive

to very sophisticated, even among village weavers. There

is a wide range of ways in which the warps are attached

to the beams, and this is reflected in many of the differences

among the end finishes that we have collected and published

on my website “End Finishes Project.” It is not silly to

look in the rugs themselves for clues to the processes

and kinds of equipment used…in that Vincent is on the mark.

But we need to put all of the information together… design

layout peculiarities, variations in the weave, kind of

weave construction, and end finishes. . I must say that

I’ve never encountered a weaver who retied all of her

individual warps or pairs of warps in the course of producing

a rug—that is sheer madness—though she may loosen ties

between the rod holding the end of her warp and the upper

warp beam. She may do this several times during the course

of weaving the rug. But this would occur with just certain

kinds of loom set-ups, and certain kinds of weave constructions.

Registered: Jan 2002 Dear

Marla,

A Yastik

Adventure: The “Denny Derivatives,” A Dread But Enjoyable Disease

![]()

Pages (2): «

1

[2]

Author

Thread

![]()

![]()

Michael Bischof

Member

Location:

Posts: 25

the idea to come close to the technical basis of weaves

I like very much ! I must confess that I did not fully

understand the consequences of what you outline here. A

"modern" loom does not result in any quality lack, if

I understand you right. So what ? Do you want to introduce a

kind of "hidden" age test applying your system of measuring

the "center" ?

Greetings,

Michael

10-26-2002 10:25 AM

![]()

![]()

Tracy Davis

Member

Location:

Posts: 5LOOMing

technology

Maybe your hypothesis could be modified to mean that a

lower "center" might be an indicator of something other

than age alone. Commercial demand for certain kinds of

rugs? (Market demand="better" looms, resulting in design

deterioration!)

10-26-2002 07:42 PM

![]()

![]()

Vincent Keers

Member

Location: Utrecht

Posts: 10

No it's not hidden, it's out there. It seems hidden, because

a lot of rugs are upside down in the books we study.

I'm finding it very disturbing that I only see, semi nomadic

new productions with the centres too high.

It's like the horizon is too high. Not natural. Feels

wrong.

Dear Tracy,

All 17'th century French production. Not one single rug

can be found that isn't pure symmetrical.

Everything had to be in perfect symmetry. The palaces,

the gardens, the rugs!

So in Europe the production had to be perfect because of

the demand.

And so it was.

I didn't study the Indian Mughal production enough.

Taj Mahal is in perfect symmetry. So the state of mind

was there. Did this influence the production?

So somewhere on the line, something changed.

The weavers? No, I don't think so.

The demand for more symmetrical rugs? Yes, in Europe.

Did this influence oriental production? Yes, I think it

did.

Couldn't they get it right before the symmetry wave went

around the world?

Yes, they could, but mostly didn't bother that much about

it.

Did this, as a consequence of lack of interest in symmetry,

led to rugs with the centres too high?

No, this led to rugs with the centres low in most pre-industrial

production.

Only when the demand for rugs increased, the production

changed, the looms changed etc.

and as a result, the centres got too high.

Think in pre-industrial production the average, oriental

loom was very simple indeed.

As a weaver you had to pull yourself up, or you had a horizontal

loom.

Thanks for sharing this very frustrating dilemma with me

for a while.

And if you look at a rug next time "18'th century", ask

yourself if the pile's up, or down.

Best regards,

v t

i n

n e

c c

e n

n i

t v

10-27-2002 01:11 AM

![]()

![]()

Michael Bischof

Member

Location:

Posts: 25

as I like any statement that comes close to the technical

basis of these weaves I want to ask you for your intentions:

do you want to find a kind of indirect measure for age

of yastiks ?

As far as I understand you there is no reason to assume

that the younger pieces, out of center as you express it,

are weaker in technical terms. Is this right ?

Greetings,

Michael Bischof

10-28-2002 06:25 PM

![]()

![]()

Vincent Keers

Member

Location: Utrecht

Posts: 10

Not only for Yastiks.

It can be used for the caucasian production also.

Have a look again at Jerry's, Ed's, Tracy,s Fachralo. Jerry's

Fachralo destroys my story but ok it's a nice test for

my idea.

It is said that Jerry's is very old because of the date

and because of the colours based on a digital image. Well

the date is 3 digits and if the image is flipped horizontal

it reads 321. If the first digit is omitted by the weaver

because this event only happens once in a thousand years?

That's more likely then omitting the last digit.

If it's 123 and the first digit was omitted then it should

be 1123. If the date is supposed to be read from right

to left it's 1231 (1321). If the date has only 3 digits

it's 123 or 321.

So in this case the 1230 date has a 20% probability. (Is

this ok Steve)

Now if we look at the centre, it's way too high.

Do we think this is normal?

Why isn't it in the middle?

So this is a sloppy production. Is it?

The dyes seem perfect. No dull madder, so that's nice.

The weaver had colours available that could astonish most

weavers.

So everything is perfect. But the weaving is sloppy?

In the lower halve the rug shows elongation and in the

upper halve it shows compression.

The knot count in the lower and the upper halve are the

same. (This is mostly the case)

Something went wrong in the production.

I think this has to do something with the looms available.

In the old productions I see rugs with the centre low (Compression

in lower halve and elongation in the upper halve)

In new production I see rugs with the centre high (Elongation

in the lower halve and compression in the upper halve)

So in the old production the weaver started with low warp

stress and ended with high warp stress.

In the new production the weaver started with high warp

stress and ended with low warp stress.

Shoot, and now I'm stuck again.

I see, but I can't explain this.

Fixed loom, high loom, low loom, roller beam loom. Weft

ease, warp depression. Cotton warps, woolen warps etc.

Maybe I'll see the light tomorrow,

I'm sure I'll see the light tomorrow,

But for now,

elongated sleep for me,

Best regards,

Vincent

10-29-2002 01:08 AM

![]()

![]()

Vincent Keers

Member

Location: Utrecht

Posts: 10I saw the

light

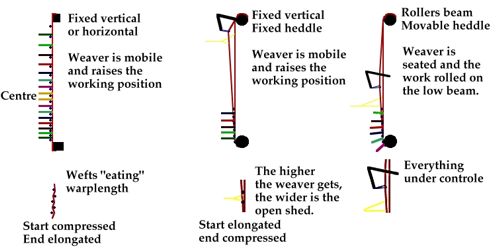

As you can see, it's very difficult to label the looms

with dates. On the other hand it does give me a sort of

extra insight in the way some rugs are made.

First loom, the most simple one, gives elongated design.

Cottage industry

Second loom, a bit more sophisticated, gives elongation

in the lower halve, compression in the second halve. Mostly

used when light weight loom is needed. Cottage industry

Third loom, most sophisticated, gives everything ok. These

are mostly used in Iran, India, Pakistan, China. Big production

centres.

I made a mistake in my previous cartoon. With a fixed heddle,

the upper halve gives compression because the warps are

more open as the work level rises. So the wefts eat less

warp length.

Why do I like yastiks? Well, to be deadly honest, I don't

like them. Designs way to big.

But I like them because of the size.

The old Yastiks are woven on the first, most simple loom.

Older cottage production

John's Yastik has been woven on the second loom. Later

cottage production.

I think this is the way things go in most, simple, cottage

production.

A Caucasian with the centre low, it's older cottage production.

Simple working conditions.

So when I see a Caucasian rug with the centre too high,

it can't be older then 1870/80. Later cottage production.

When I see a Caucasian rug with everything under control,

it's more likely a 1910/1930 production. Russian production.

And because everyone thinks I'm crazy as can be,

I'll give myself a,

and I'll return to my private dark dungeons.

Best regards,

Vincent

10-29-2002 11:31 PM

![]()

![]()

Marla Mallett

Member

Location: Atlanta, Georgia

Posts: 4

With a fixed warp, several things can happen. First, the

tension can increase, causing wefts to pack down more tightly

in a weft-faced weave. This is the kind of foundation we

find in most Caucasian and Turkish rugs. What you describe

as wefts “eating” warp length is real indeed: In weavers’

terms this is “warp take-up.” In such a case, in the second

half of the rug the wefts would pack more tightly, and

the design would be more compacted, not looser and more

spread out. It’s a different matter with weaves that are

not weft-faced.

Second, depending upon atmospheric conditions, wool warps

can stretch and become looser. In this case, a weft-faced

weave would tend to spread more vertically toward the top

end.

Another factor: weaver fatigue. I don’t know any weaver

who doesn’t get eager to finish a piece when it’s been

on the loom for a long time. Thus there is a natural human

tendency to occasionally skip rows in some parts of the design

near the top end, compacting the layout. Of course miscalculations

in the warp length and design can also cause weavers to

shorten a design at the top—a possibility that many people

have commented on in the past.

For me, the easiest explanation of regular versus irregular

layouts is probably commercial pressures. If weavers know

that straight and symmetrical pieces bring better prices,

they’ll try hard to produce such items if they’re serious

about selling their rugs—no matter what kind of loom they’re

working with. Fancier roller beam looms certainly helped

them to achieve such products.

Best,

Marla

10-30-2002 05:35 PM

![]()

![]()

Vincent Keers

Member

Location: Utrecht

Posts: 10Oi!

You make me very happy indeed. Think you're much to gentle

with me.

It's like this.

I see something. For me it's very obvious. (Mostly the

case with lunatics)

Nobody else seems to see the same thing, and the more I

think it's ignored, the more I'm obsessed with it. (Mostly

the case with lunatics)

So get ready for my block headed reply.

If all high centre rugs are made on fixed looms, modern

production is in big shit. Cause, it's all I see nowadays

in the semi-nomadic

Iranian/Kurdish production.

If the warps are fixed and tightly fixed the wefts will

eat warp length (pick up).

The tighter the warps get, the more difficult it is to

get the wefts true. Anyone can practice this on a small,

"do it your self" made loom.

If, however, the wefts are given more length, more sinuous,

the rug will get wider when finished. (Don't think that's

the solution)

And, I do understand that a weft-faced weave gives no problems.

But the weft-faced weave is the construction platform

for the knots.

The wefts need to be "laid in' more straight, tight, then

in a kilim construction. (A kilim needs to be pliable)

If the fixed loom is equipped with a fixed heddle, then

elongation is in the lower halve. This is what you can

see in the Moroccan production.

This is loom nr. 2 in my cartoon above. I have some "Haut

Atlas" production that shows this very conveniently.

Yes, wool warps stretch and get hurt every time the wefts

are pulled true. I've been thinking about this for a while

and came up with this:

Wool isn't like elastic. If stretched, then they stay stretched

so this has nothing to do with elongation. Only less tight

woollen warps in the finished rug.

But if it's only happening with woollen warps, I don't

think I could have invested the time in this subject. With

cotton warps, it's even more obvious, because cotton will

not stretch that easy. But we only have to look at Kurdish/Hamadan

production to see what has happened especially in the

Kelly

production.

Weavers getting tired of weaving do very strange things

at the upper border design. I know this, and a simple knot

count will show this.

Here it's even more clear: The rug starts compressed, then

becomes elongated in the second halve (same knot count)

but then the border gets very compressed suddenly and yes it

has a lower knot count so the weaver was 1. Tired 2. Run out

of warp length (because of elongation)

But it can be rather disappointing news for some people.

Because a 1309 AH dated Caucasian rug could be 1931 AC

instead of the 1892 AC.

Oops! Wrong calendar.

I will not yet start with taut wefts and depressed warps.

Because then my story is much to easy.

Thanks for the help,

Vincent

Checking out again

10-31-2002 12:52 AM

![]()

![]()

Marla Mallett

Member

Location: Atlanta, Georgia

Posts: 4

I don’t think the same factors apply with cotton warps and

Hamadan single-weft constructions as with the Turkish and

Caucasian wool weft-faced constructions. I think your theory

fits pretty well with the Hamadan weaves—THEY are NOT

weft-faced, and as the weaving progresses, such a weave should

indeed tend to spread vertically on a fixed warp in the

top half as you show in your diagram.

Of course when we talk about fixed warps, we have to remember

that similar conditions apply if the warp is a continuous

one that encircles the two beams—one in which the rug is

pulled around and up on the back side of the loom as the

weaver goes along. Such a warp is also of a fixed LENGTH.

Anyone who has done any tapestry weaving (where the weave

is WEFT-FACED) knows for sure that whenever the warp tension

is uneven, it’s in areas where the warp is LOOSER that

the sinuous weft does not pack down as well. Such a weft

compacts best where the warps are tight.

I’m glad that I’m not the only one who comes up with theories

sometimes viewed as wacky!

Best,

Marla

10-31-2002 01:43 AM

![]()

![]()

Unregistered

Guest

Location:

Posts: N/A

Congratulations on your epiphany!

Think of a loom as just another string instrument -- say,

a guitar. Say you know how to play a tune in the key of

"G" but want to play it in "A" and you don't know how to

read music. You can put a devise across the neck of the

guitar that will depress all the strings on a certain fret

which will change the key to "A". Imagine that this devise

is a heddle bar and that the thing that holds the lower

end of the guitar strings in place is the rug's fell line.

The closer the fixed ends of the guitar strings, (the

fell line), is to the devise depressing the guitar strings,

(the heddle bar and heddles), the higher the notes will

sound which is analogous, in weaving, to compression.

Early vertical cottage loom's warps were wrapped on sticks

stuck into the ground and then one of the sticks was strapped

to the lower loom beam. On these looms the lower beams

were movable and the upper beam was fixed. Warp tension

was adjusted from below. The upper end of the warps were

removed from the wrapping stick and tied, by twos, to the

upper beam. Their long loops, (which would be for the latter

part of the rug), hung toward the back of the loom. As work

progressed, and the fell line approached the heddles, the

tension on the warps would increase whenever the shed was

changed. At this point all of the looped warps tied to the

stationary upper beam would have to be untied so the rug

could be pulled down and around. Then they would all have

to be retied to the upper beam. Then the tension would

have to be reestablished. I don't know, but I imagine that

most of the rugs made on these looms were about twice as

long as they are wide just to keep this drudgery to a

minimum. At least that's the way I would do it, half and

half.

So, in other words, I think you can solve your dilemma.

Factor into your figuring this new stuff and the effect

on warp tension the ratio of space between the fell line

and the heddles has on rug compression. You're almost there.

Sue

10-31-2002 06:55 AM

![]()

![]()

R. John Howe

Member

Location:

Posts: 22

I am not a weaver and have not grappled with the issues

of warp tension and weft ease first hand, and it is true

that sometimes nomadic weavers had to take up a loom with

an uncompleted piece on it to follow the sheep, water and

grass, but ----

it is my understanding that even tribal weavers made great

efforts not to move a loom or to disturb the warps seriously

unless this was absolutely necessary.

I have not heard that it would be a routine thing to weave

half of a rug that is twice its width and then readjust the

unfinished piece on the loom so as to weave the second

half. That would predictably cause serious problems as the

result of the inability to re-establish the original warp

tension.

The horizontal Turkman demonstration loom I worked with

last summer at the Folklife Festival had been built for

the rug being woven on it (which would be when completed

about 4 X 6 ft). That loom was long enough to permit that

size to be woven without any readjustment of warps. I think

the usual strategy was to build the loom long enough to

permit the rug to be woven on it without disturbing the

warps.

Regards,

R. John Howe

10-31-2002 10:10 AM

![]()

![]()

Steve Price

Administrator

Location:

Posts: 37A note

about posting as "unregistered"

One of the messages in this thread, signed "Sue", shows

up with Unregistered as the user name in the left hand

column. This might be a good time to say a few words about

how to avoid that.

For registered members who are logged in, the software

will automatically fill in your name and display it. For

people who are not registered or for registered people

who are not logged in, the screen that lets you type in

your message if you are posting has a field called "user

name", and that field will have the word "unregistered" already

in it. It shows up as being gray, like a word that can't

be edited or selected in many Windows applications. But,

in fact, it can be overwritten and will display the name that

gets typed in.

We prefer full names - most of the time we insist on them

- so, please, if you get the "unregistered" user name in

that field, overwrite it with your own name.

Thanks,

Steve Price

10-31-2002 10:33 AM

![]()

![]()

Marla Mallett

Member

Location: Atlanta, Georgia

Posts: 4

The one loom characteristic that has NOT seemed to change

throughout Western and Central Asia is the kind of shedding.

Unlike most other weaving done by primitive peoples around

the world, virtually all Asian rug makers have used a fixed

heddle arrangement—that is the primary shed is held open

constantly, and a secondary shed is opened or partially

opened within this. The heddle rod may be moved along the

warp as the work progresses--propped up on rocks if it’s

a horizontal loom, or moved up the frame if the loom is

vertical. But the primary shed is NOT opened and closed

as the work is done. That’s too difficult with the tension

required on a closely set rug warp.

Best,

Marla

10-31-2002 07:27 PM

![]()

![]()

Vincent Keers

Member

Location: Utrecht

Posts: 10

A quote:

"I don’t think the same factors apply with cotton warps

and Hamadan single-weft constructions as with the Turkish

and Caucasian wool weft-faced constructions. I think your

theory fits pretty well with the Hamadan weaves—THEY are

NOT weft-faced, and as the weaving progresses, such a weave

should indeed tend to spread vertically on a fixed warp

in the top half as you show in your diagram."

This is the problem. In Hamadan, Kurdish kelly sizes, it's

compression in the top half, and crystal clear elongation

in the lower half.

Woollen warps, cotton warps or whatever warps. This is

what we're getting nowadays and for the last 120 years.

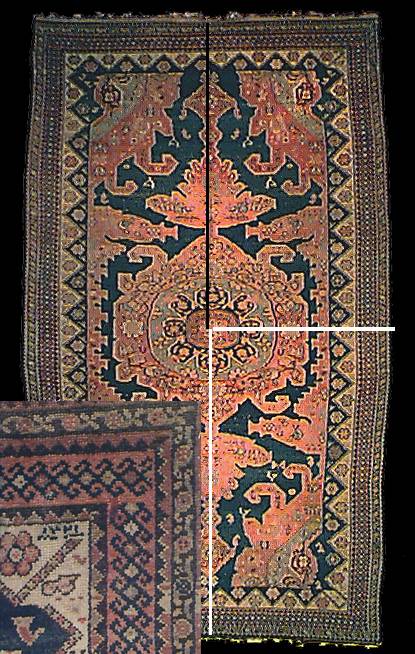

I have a dated 1221?!, (That's what is says) sort of Malayer.

It's ±292 x 173 cm.

Single weft construction. Warps Z2S ply & wefts 2S ply

wool mixed brown/white.

Knots: Wool. 2 singles. No twist visible. Symmetrical.

This rug doesn't show signs of compression. It's 5 cm's

elongated in the top half.

It's perfect for me, because the centre is grounded and

the centre is the centre. It just feels right.

Some of us may feel the colours are all wrong. So be it.

The construction is great, the weaver was an ok crook and

maybe the dye-master was a crook

or "they" just liked it this way. I like Pop-art as well,

so sorry.

(Image)

And, for the moment I'm grounded. I know you're right,

but I can't stand it.

Not because you're right and I'm looking for clues that

can't be found, I think, but because I keep on seeing things!

Help, here it comes again.

No, I'll keep on banging this drum for the rest of my life

or as long "they" are feeding us rugs with the centres

to high.

Think in the end, I have to agree with you, after all.

"Sloppy jobs" Which makes this a two year lasting discussion.

Best regards,

Vincent the elongated (slow) thinker.

PS. But if plain-weave, all wool rug, has been knotted

on a horizontal, fixed loom? No heddle, no shed. Pull up

the warps with fingers. The wool warps have to untwist,

or elongate, because of the stress. That could result in

elongation in the top half.

Ooops.

![]()

![]()

All times are

GMT. The time now is 06:27 AM.

Pages (2): «

1

[2]

![]()

A

Powered

by: vBulletin Version 2.2.6

Copyright ©2000, 2001, Jelsoft Enterprises Limited.